Company

About Polyplan

Passion for Automation

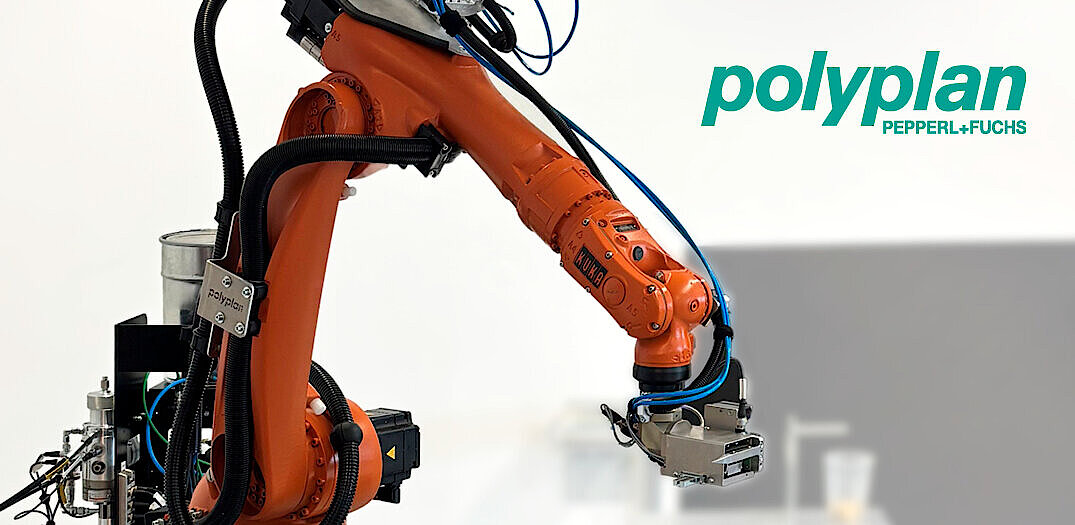

For over 30 years, Polyplan has led the way in robotic automation and advanced polyurethane processing. In the automotive sector, the company sets benchmarks with its NVH foaming and rustproofing solutions. At the same time, Polyplan develops high-precision equipment for the logistics industry, including solutions for automated palletizing and depalletizing.

As part of the Pepperl+Fuchs Group, we leverage global resources to drive innovation. With over 90 installations operating worldwide, a strong focus on sustainability, and a dedicated team, Polyplan is a trusted partner for efficient, cutting-edge manufacturing and material handling solutions. Polyplan: Your automation, our passion – your solution for future-ready, high-performance processes.

Polyplan founded

Entry into the automotive industry

Delivery of first fully automated NVH foaming

Delivery of first fully automated cavity preservation system

Launch of HD-PUR 100HR high-pressure dosing/dispensing unit

Founding of Polyplan China: Polyplan Engineering (Dalian) Co., Ltd

Introduction of the first VMT Vision solution for palletizing and depalletizing

Launch of compact HD-PUR 100C system

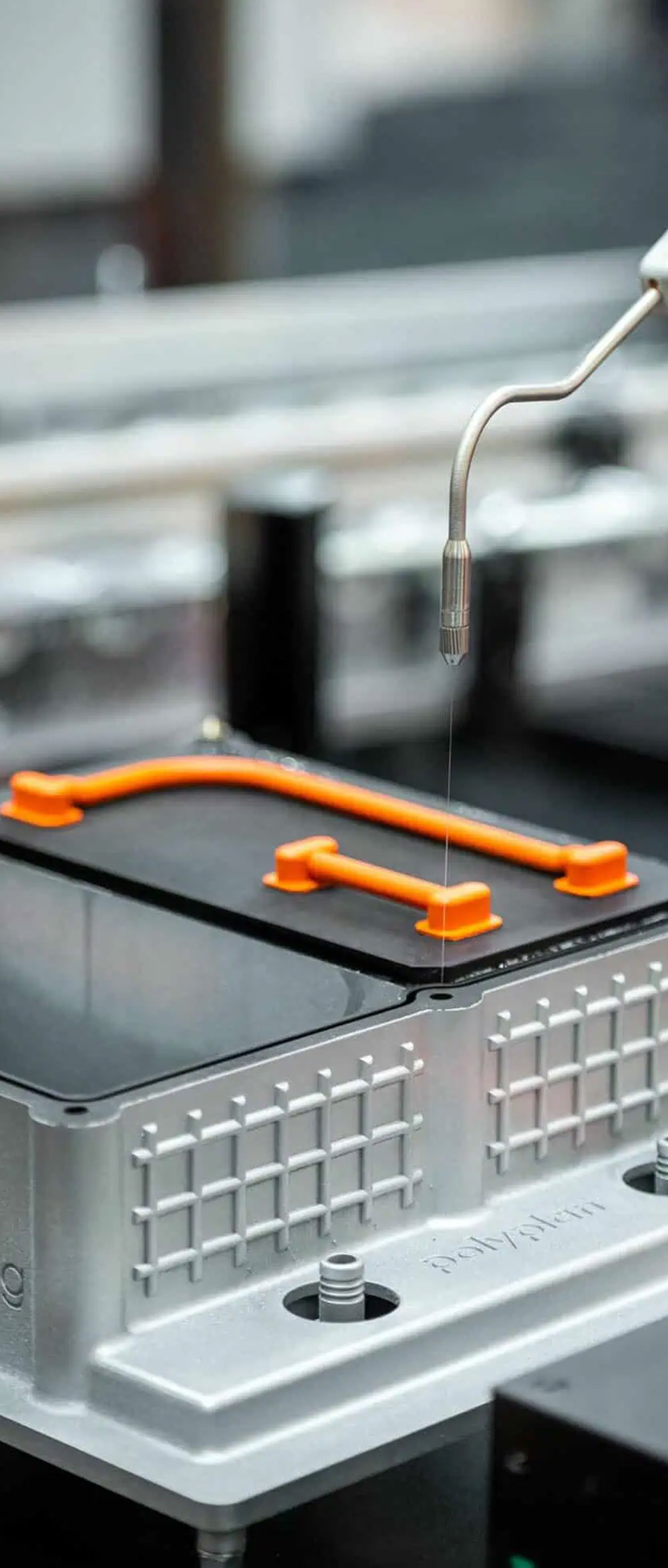

Launch of ToolBox 3D Blacklight for measuring liquid beams and cones

Launch of HD-PUR 100AS high-pressure dosing/dispensing unit

Fully owned memeber of Pepperl+Fuchs SE

Introduction of AirMix functionality for cavity preservation systems

Member in newly formed Division Factory Solutions withinP+F Group

Delivery of first complete, completely integrated and ready-to-use depalletizing solution

Relocation of Polyplan China from Dalian to new facility in Changchun

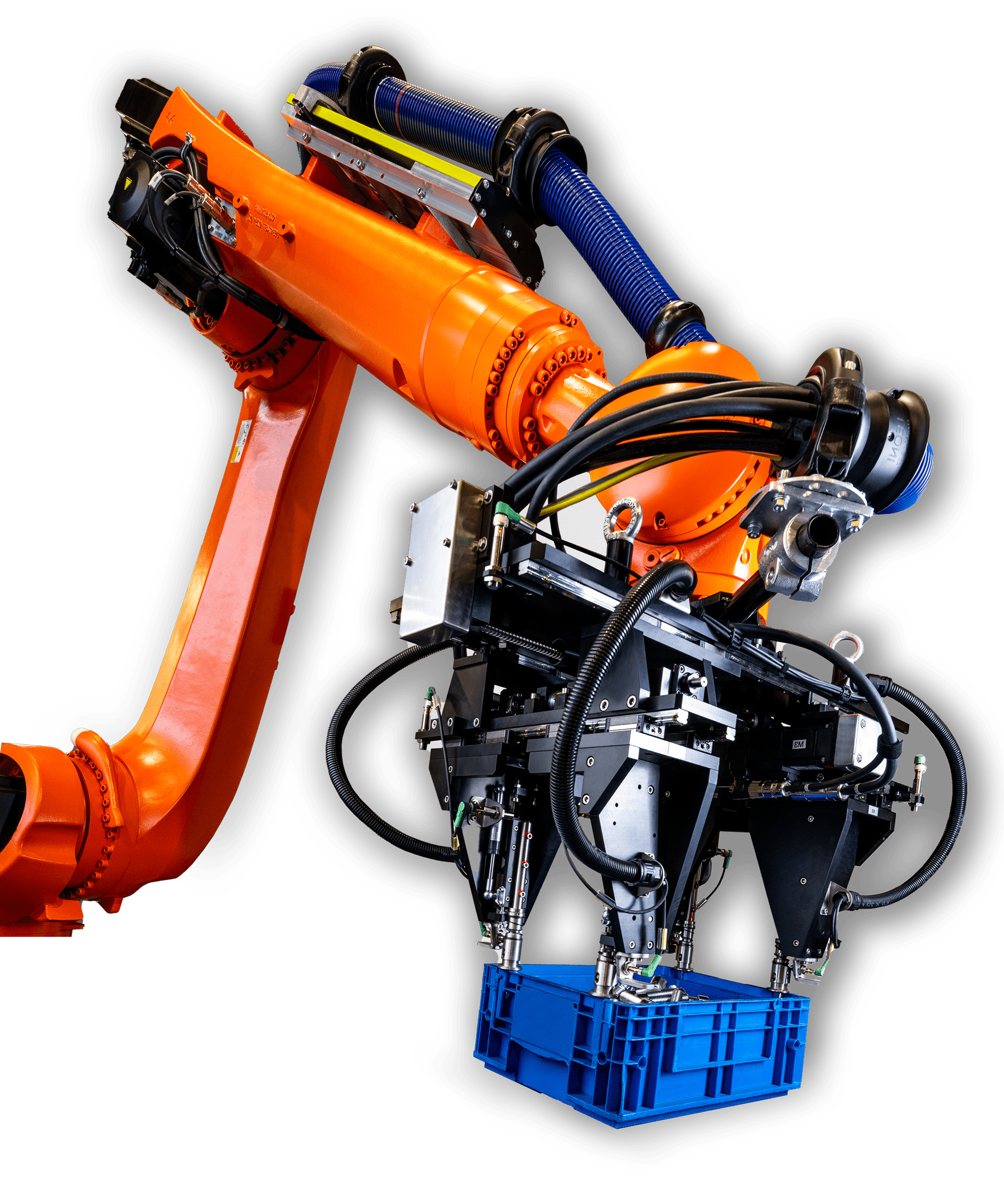

Development of proprietary tote grippers for 8,000-series containers (size related) and lid removal

Delivery of first fully automated palletizing and depalletizing system to customer

Launch of multifunctional gripper – add-on for handling expanded polypropylene lightweight boxes“ boxes and cartons

Coming soon: Opening of Polyplan’s US Sales & Service Office in Ann Arbor, near Detroit, MI

Sustainability

Rethinking Sustainability in Production and Logistics

Resource efficiency and environmental responsibility are becoming increasingly important in both production and logistics. Modern technologies make it possible to design processes that reduce environmental impact and optimize resource use – without compromising on quality or performance

Polyplan delivers sustainable automation solutions that set benchmarks in both the automotive and logistics industries. Our acoustic foam injection systems enhance vehicle comfort and safety, while our automated palletizing and depalletizing solutions improve efficiency and precision in logistics. Throughout all our innovations, we remain focused on one key goal: aligning sustainability with progress.

Sustainability Through Deliberate Material Selection

Our NVH foaming machines are designed to operate safely with recycled materials, such as polyol and isocyanate recyclates. The unrestricted use of renewable materials can reduce petroleum consumption by up to 20%. Additionally, incorporating reusable multi-use filters cuts waste from disposable filters by up to 70%.

Sustainability Through Repairability, Long System Lifespan and Non-Destructive Quality Control

Our acoustic foam injection systems exclusively use wear-free magnetic couplings in their drive trains, providing a lifespan approximately ten times longer than mechanical seals. This ensures sustainable and efficient system operation with high availability. Additionally, all potential high-wear components are repairable and are refurbished rather than discarded in the event of damage – which often more than doubles their service life.

When shipping replacement parts, we primarily use reusable closed-loop packaging to minimize packaging waste. Nearly all modules in our systems are also protected by durable fixed piping, which reduces both replacement efforts during operation and waste generation by approximately 30%.

Sustainability Through Energy-Efficient System Technology

Using energy-efficient temperature control units to heat acoustic foam components reduces the heating energy needed by up to 20% compared to other systems. Dynamic temperature compensation and efficiency-optimized pump speed control save an additional 10% of the energy required to manage the temperature of the PU components. Our systems are also equipped with high-performance thermal insulation, cutting total heating energy needs by up to 40%. The standby during shorter downtimes further reduces energy use by up to 30%.

Sustainability Through New, Compact Design

Our new high pressure dosing unit HD-PUR 100AS and UC reduce physical footprint by up to 80% compared to the proven HD-PUR 100HR high-pressure unit, improving space utilization and overall system efficiency. With these sustainable automation solutions, we actively reduce environmental footprint, optimize resource use, and enhance both efficiency and competitiveness.

Our Values

Living Our Values Every Day Is the Foundation of Our Success

Our values are the cornerstone of everything we do. They serve as a compass, guiding us in our daily work and helping us achieve success together with our partners and customers. To uphold these principles, we have developed a Code of Conduct — a set of guidelines ensuring ethical and lawful behavior in all business activities.

Innovation

We think ahead and develop solutions that drive technological progress. With over 30 years of experience, we deliver state-of-the-art systems that meet today’s demands while being ready for the future.

Sustainability

Our mission is to optimize processes while reducing environmental footprint. We see resource-saving technologies and efficient automation as the key to sustainable industrial production.

Excellence

Quality is our top priority. Every solution we offer is designed for maximum precision and reliability – delivering optimal efficiency and long-term success stories.

Responsibility

We are aware of the consequences of our actions and always act with the big picture in mind.

Credibility

Our actions are fully aligned with what we think and communicate. We believe in transparency and stand by our word.

Trust

We see mutual trust as the foundation of successful, collaborative partnerships.

Partnership

We see ourselves not just as a supplier, but as a long-term partner. Through close collaboration with our partners, we develop customized solutions that create real value – we are your strategic ally for future-ready solutions.

Competence

Our competence for acting effectively is built on our technical expertise, social skills and structured problem-solving abilities.

Reliability

We honor our commitments regarding deadlines, tasks and requirements – both in our relationships with customers and colleagues.

Team Spirit

We achieve our goals through the strength of a highly motivated team that collaborates and supports one another.

Joy in Our Work

We enjoy what we do and celebrate our successes, drawing energy and satisfaction from them.

As part of the Pepperl+Fuchs Group, Division Factory Solutions combines three leading companies – Polyplan GmbH, Neoception GmbH, and VMT Vision Machine Technic Bildverarbeitungssysteme GmbH – into a powerful network. Together, we deliver customized solutions that optimize your production processes and help you achieve your goals faster and more efficiently.

Solutions

At Polyplan, customized automation solutions are at the core of what we do. Whether in the automotive industry, battery production for e-mobility, or logistics, we deliver cutting-edge technologies that enhance efficiency, ensure precision, and promote sustainability.

From robot-guided Polyurethane (PUR) acoustic foam systems and innovative door waxing solutions to automated palletizing and depalletizing systems for various packaging formats and containers – our tailored automation solutions not only provide precision and efficiency but also secure your long-term competitiveness.

General Terms of Delivery | Software Clause

Automotive

Logistic

Battery Technology

Technical Center

Automotive

Logistic

Battery Technology

Technical Center

Team

Polyplan is more than just an employer – we are an international team that embodies innovation and sustainability. With our headquarters in Germany, an office in Changchun, China, and soon another location in the US, we are shaping global solutions for a forward-thinking industry. As a subsidiary of the renowned Pepperl+Fuchs Group, we benefit from a strong network and resources that drive our worldwide success. Our customers – including leading names like BMW, Mercedes, and Lamborghini – value our expertise and reliability.

We combine international presence with a corporate culture that values personal development and flexibility. Discover our management team, learn about our leadership positions, and find out about the exciting career opportunities that await you with us. Become part of a team that thinks globally and acts locally – for the industry of tomorrow.

Team

Foresight and Experience – Our Team

At Polyplan we rely on a strong leadership team that shapes the future with long-standing experience, an innovative spirit, and a clear vision. Thanks to our global network, our team develops tailored solutions that are precisely aligned with your needs and – through this and other benefits – set new standards.

Our team stands for

Careers

Shape the future with us! Polyplan offers the opportunity to work in an innovative, international environment focused on efficiency, sustainability and continuous personal development. As specialists in automation solutions, we focus on dosing technologies in the automotive industry – such as acoustic foam systems or cavity preservation systems – and especially on the automation of logistics processes, like automated de-/palletizing of small load carriers and other containers.

Our solutions range from flexible, manual machines to highly complex robotic systems. Working at Polyplan means being part of a dynamic team, developing future-proof, sustainable solutions for the automotive industry and logistics sector together.

Seize the opportunity to advance your career in a globally oriented company with room for ideas and growth!

Company Culture

Polyplan offers its employees numerous benefits that go beyond the ordinary. These include:

News

FROM MANUAL TO AUTOMATED – WHY POLYCUT IS WORTH IT

GAMECHANGER IN INBOUND LOGISTICS: POLYCUT AUTOMATES STRAPPING REMOVAL

PEOPLE OF POLYPLAN – ENGINEERING AROUND THE WORLD

Corrosion Protection by Robot: Sustainable Cavity Preservation for Vehicle Doors and Tailgates

Corrosion prevention by robot: Protecting battery packs from corrosion in the long term

Depalletising small load carriers by robot: variable crate picking every second

Corrosion Protection by Robot: Sustainable Cavity Preservation for Vehicle Doors and Tailgates

FROM MANUAL TO AUTOMATED – WHY POLYCUT IS WORTH IT

GAMECHANGER IN INBOUND LOGISTICS: POLYCUT AUTOMATES STRAPPING REMOVAL

PEOPLE OF POLYPLAN – ENGINEERING AROUND THE WORLD

Corrosion Protection by Robot: Sustainable Cavity Preservation for Vehicle Doors and Tailgates

Corrosion prevention by robot: Protecting battery packs from corrosion in the long term

Depalletising small load carriers by robot: variable crate picking every second

Corrosion Protection by Robot: Sustainable Cavity Preservation for Vehicle Doors and Tailgates

Highlights

Milestone Projects & Installations

Our “milestones” offer an overview of outstanding projects that highlight Polyplan’s expertise in developing innovative automation solutions. Our customers include leading companies in the automotive and logistics sectors across Europe, the US, Japan, India and China, as well as nearly all major vehicle manufacturers worldwide. Together, we create tailored, efficient and sustainable solutions – delivering real value for our customers.

- Select Everything

- PUR (POLYURETHANE) Acoustic Foaming

- Cavity preservation / Door waxing

- Fully Automated De-/Palletizing

![[Translate to English:] Geeignete Materialwahl](/fileadmin/_processed_/1/1/csm_suitable-material_38af2b3a33.jpg)

![[Translate to English:] Lange Anlagenlebensdauer](/fileadmin/_processed_/2/7/csm_long-lifespan_e14ad33a26.jpg)

![[Translate to English:] Energieeffiziente Anlagentechnik](/fileadmin/_processed_/c/c/csm_energy-efficient-tech-_7a75f16303.jpg)

![[Translate to English:] Neue, kompakte Bauweise](/fileadmin/_processed_/a/9/csm_compact-design_89cfb6e373.jpg)

![[Translate to English:] Audi](/fileadmin/user_upload/audi.png)

![[Translate to English:] BMW](/fileadmin/user_upload/bmw.png)

![[Translate to English:] FAW](/fileadmin/user_upload/faw.png)

![[Translate to English:] lamborghini-bw](/fileadmin/user_upload/lamborghini-bw.png)

![[Translate to English:] geely](/fileadmin/user_upload/geely.png)

![[Translate to English:] magna](/fileadmin/user_upload/magna.png)

![[Translate to English:] benz](/fileadmin/user_upload/mercedesbenz.png)

![[Translate to English:] mini](/fileadmin/user_upload/mini.png)

![[Translate to English:] seat](/fileadmin/user_upload/seat.png)

![[Translate to English:] skoda](/fileadmin/user_upload/skoda.png)

![[Translate to English:] volvo](/fileadmin/user_upload/volvo.png)

![[Translate to English:] vw](/fileadmin/user_upload/vw.png)

![[Translate to English:] porsche](/fileadmin/user_upload/porsche.png)

![[Translate to English:] durr](/fileadmin/user_upload/durr.png)

![[Translate to English:] tesla](/fileadmin/user_upload/tesla.png)

![[Translate to English:] fft](/fileadmin/user_upload/fft.png)

![[Translate to English:] siemens](/fileadmin/user_upload/siemens.png)

![[Translate to English:] sar](/fileadmin/user_upload/sar.png)

![[Translate to English:] ae-industry](/fileadmin/user_upload/ae-industry.png)

![[Translate to English:] vdl](/fileadmin/user_upload/vdl.png)